Home - Family

- Healthcare - Work

Photos

- Politics

My Music: The Gem City Flyers 1984 - Caravan 1993

Caravan 1994 - Caravan Audio - My Other Recordings

My Music: The Gem City Flyers 1984 - Caravan 1993

Caravan 1994 - Caravan Audio - My Other Recordings

University of Washington

Applied

Physics Department

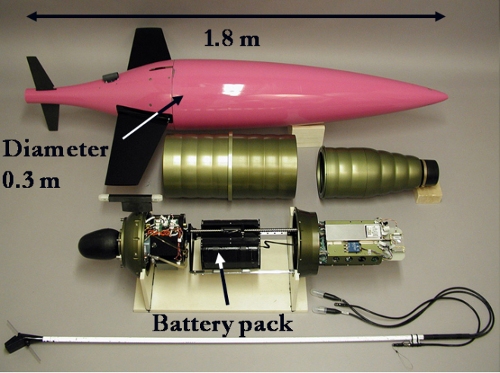

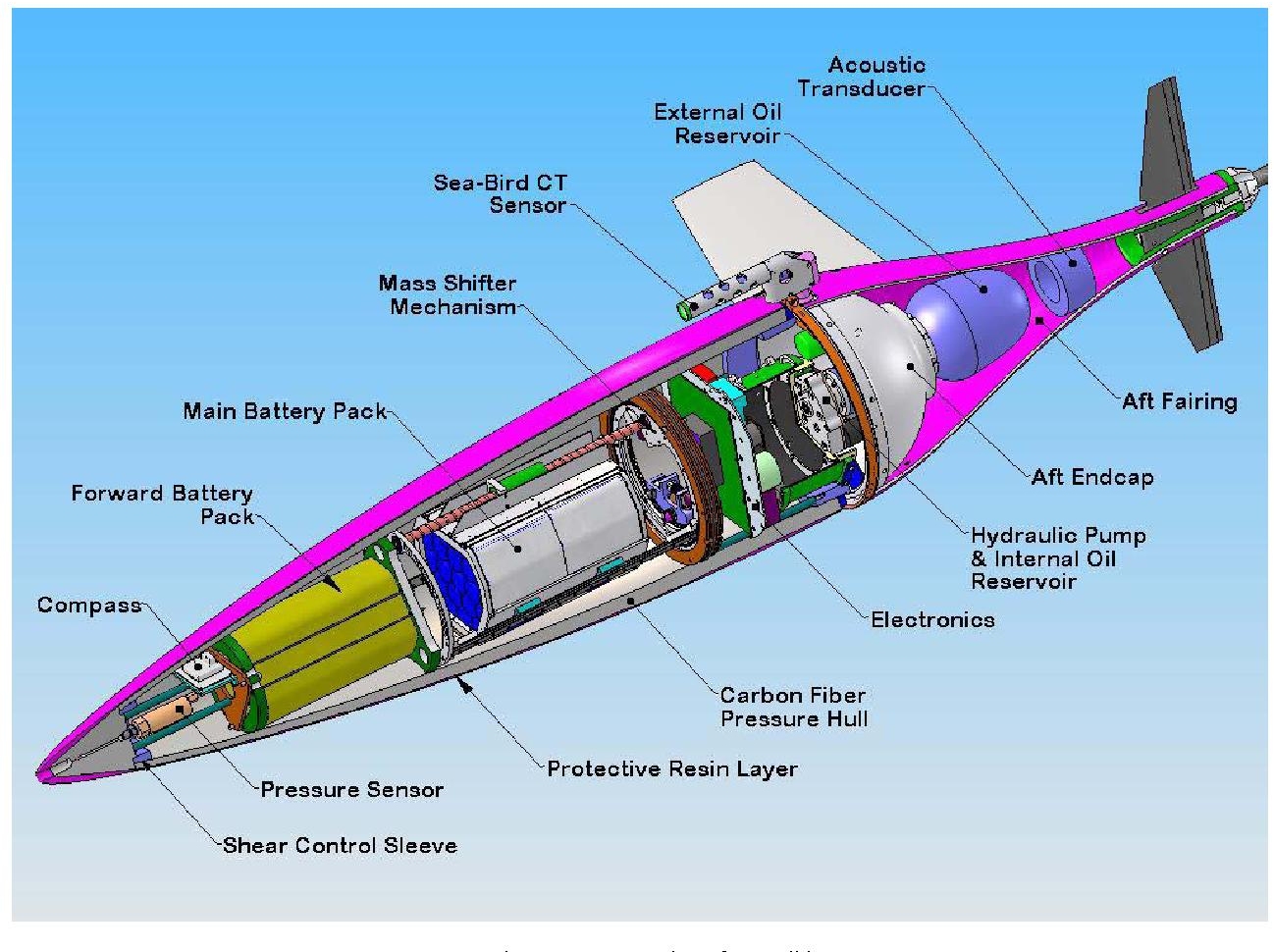

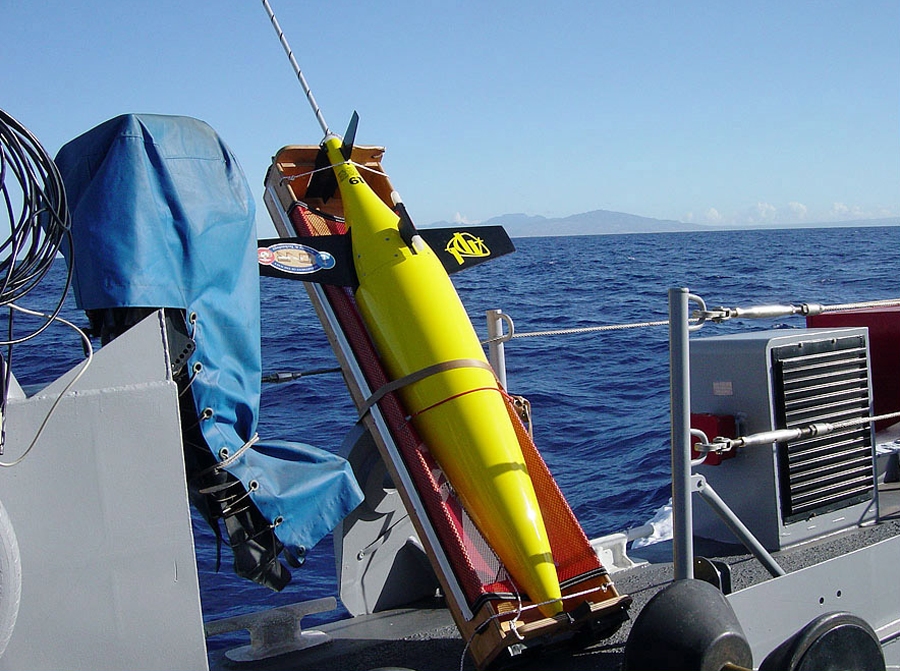

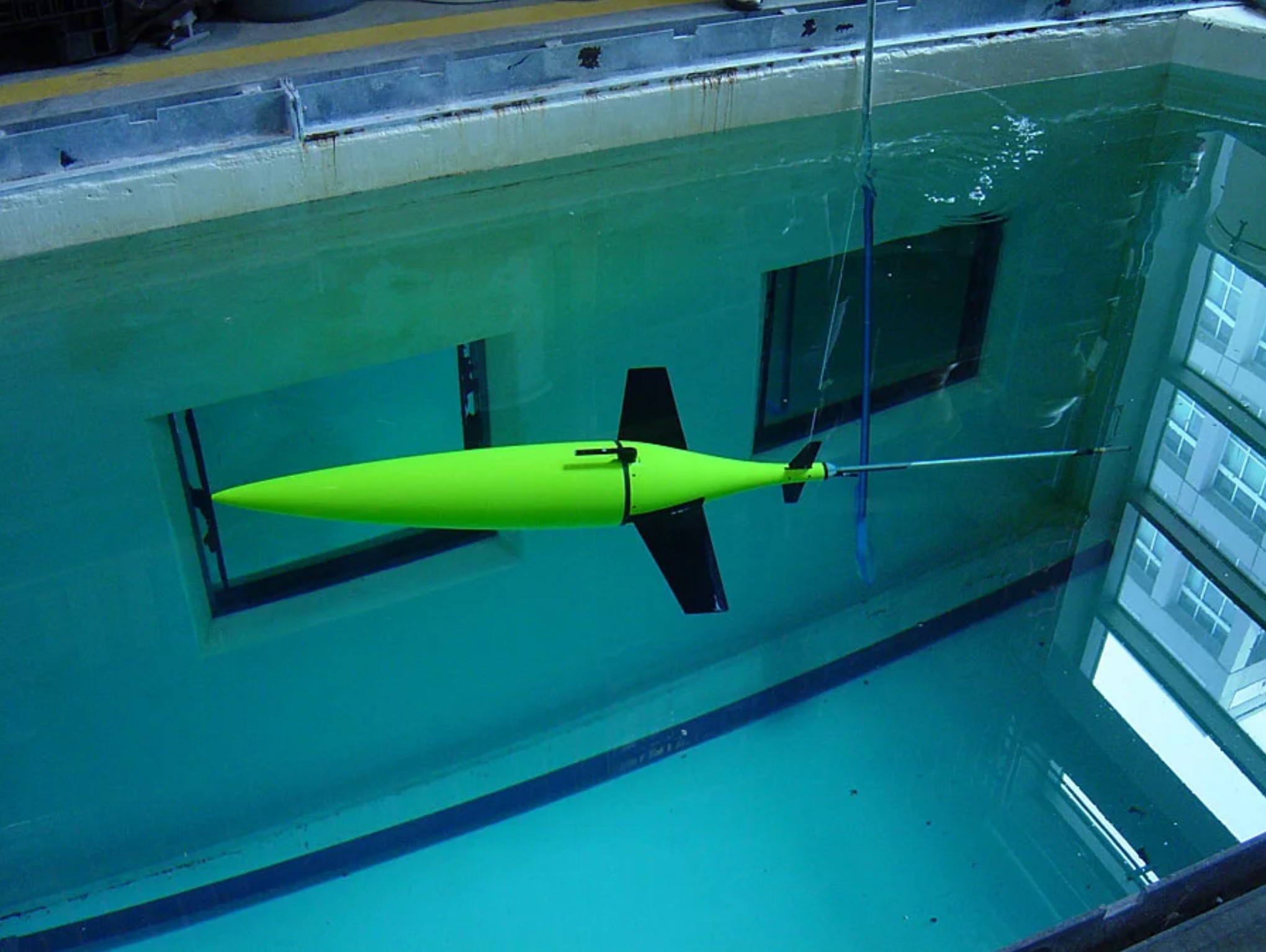

Seaglider Program: 1,000 Meter Depth

Record for longest deployment and travel - using no propellers, it travels silently

It moves forward by changing its buoyancy - propelling it by sinking and rising

The black bladder inflates and deflates with oil to change the buoyancy

Project closed in 2018 after supplying more than 125 Seagliders and 8 Deepglider

Transferred to another manufacturer I believe

Seaglider Project - on YouTube

Seaglider Program: 1,000 Meter Depth

Record for longest deployment and travel - using no propellers, it travels silently

It moves forward by changing its buoyancy - propelling it by sinking and rising

The black bladder inflates and deflates with oil to change the buoyancy

Project closed in 2018 after supplying more than 125 Seagliders and 8 Deepglider

Transferred to another manufacturer I believe

Seaglider Project - on YouTube

________________________________________________________________________

University of Washington

Astronomy / Physics Department

Four Axis Machining of a Support Arm for the Large Hadron Collider

The Largest Particle Collider in the World

My Program and Setup Tooling being run by co-worker Peter, after I left the UW

|

Four Axis Machining On The "Small Dahlih" CNC Mill |

________________________________________________________________________

University of Washington

Physics / Astronomy Department

Deepglider Project - 6,000 Meter Depth

In Collaboration With

U.W. Applied Physics and designer Jim Osse

The initial stock was too large a diameter to fit over the cross-slide.

I used our largest steady rest to machine a section down to fit over the cross-slide.

No photos of that setup, but a photo showing the minimum clearance that created.

I had to flood the cross-slide to prevent chips from getting caught under the stock.

Photo shows tool block with two tools, but of course I only had one installed each time.

________________________________________________________________________

University of Washington

Physics / Astronomy Department

________________________________________________________________________

Intellectual Ventures Lab

ARKTEK - Manufactured by Aucma Global

A Passive Vaccine Storage Device - PVSD

Prototypes I built and helped to design.

One is partially cutaway to show the inner chamber, insulation and bellows neck.

An inner chamber testing our insulation wrapping device with toilet paper as a cheap test material.

|

|

|

From Right to

Left

Inner Chamber Prototype Showing Bellows Neck and Test Insulation. The neck design greatly increases the distance for heat to travel from outside to inside. Three Prototypes - good for over a month of vaccine storage. Two early commercial versions. One current ARKTEK commercial PVSD. |